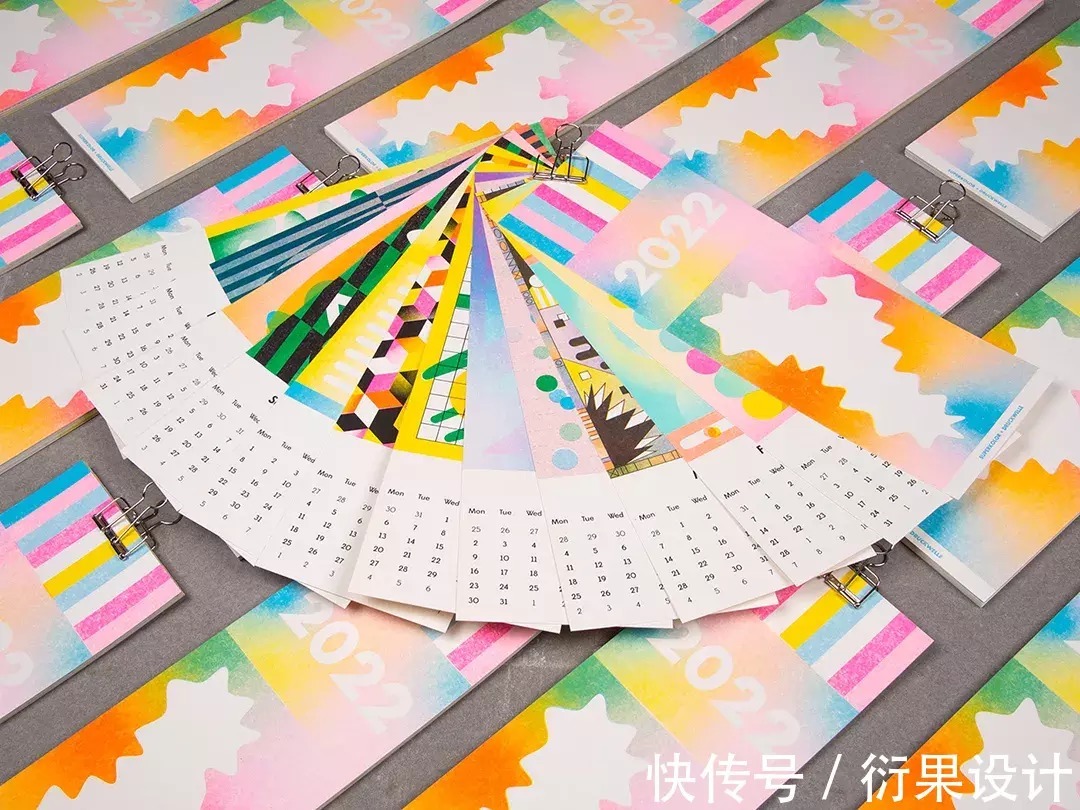

е№ізүҲеҚ°еҲ·еҸҲз§°дёәиғ¶еҚ°пјҢжҳҜдёҖз§ҚжңҖеёёз”Ёзҡ„еҚ°еҲ·ж–№ејҸе®ғжҳҜз”ұж—©жңҹзҹізүҲеҚ°еҲ·еҸ‘еұ•иҖҢжқҘзҡ„пјҢжӯӨеҗҺеҸҲж”№иҝӣдёәз”ЁйҮ‘еұһй”ҢжҲ–й“қеҒҡзүҲжқҗпјҢе…¶зү№зӮ№жҳҜеҚ°зә№йғЁеҲҶдёҺйқһеҚ°зә№йғЁеҲҶеҗҢеӨ„еңЁдёҖдёӘе№ійқўдёҠпјҢеҲ©з”ЁжІ№ж°ҙзӣёж–Ҙзҡ„еҺҹзҗҶпјҢжҠҠеӣҫеғҸеҚ°еҲ·еҲ°дёҖдёӘж©Ўзҡ®иғ¶еҚ°ж»ҡзӯ’дёҠпјҢеҶҚз”ұж»ҡзӯ’жҠҠеӣҫеғҸеҚ°еҲ°зәёдёҠгҖӮиғ¶еҚ°жңәжңүеӨҡдёӘеҚ°еҲ·иЈ…зҪ®пјҢеҸҜд»Ҙдј йҖҒдёҚеҗҢзҡ„йўңиүІгҖӮе№ізүҲеҚ°еҲ·еҘ—иүІеҮҶзЎ®гҖҒеҲ¶зүҲз®ҖдҫҝгҖҒжҲҗжң¬дҪҺе»үгҖҒиүІи°ғжҹ”е’ҢгҖҒеұӮж¬Ўдё°еҜҢгҖӮ

еҮёзүҲеҚ°еҲ·жҳҜжңҖж—©еҸ‘жҳҺзҡ„пјҢ并且жҳҜдёҖз§ҚжңҖеҸӨиҖҒзҡ„еҚ°еҲ·жҠҖжңҜпјҢе…¶зү№зӮ№жҳҜе°ҶзүҲйқўеҮёеҮәйғЁеҲҶзҡ„еӣҫеғҸе’Ңж–Үеӯ—дёҠиүІеҗҺзӣҙжҺҘеҚ°еңЁзәёдёҠгҖӮе®ғзҡ„еә”з”ЁеҺҹзҗҶе°ұеғҸзӣ–еӣҫз« пјҢеҮёиө·зҡ„ең°ж–№зқҖеўЁпјҢзӣҙжҺҘеҚ°еңЁжүҝеҚ°зү©дёҠгҖӮиҝҷз§ҚеҚ°еҲ·ж–№ејҸдёҚиғҪеҚ°еҲ¶еӨҡеұӮж¬ЎгҖҒиүІеҪ©дё°еҜҢзҡ„еҚ°еҲ·е“ҒпјҢе…¶иЎЁзҺ°еҠӣеҸ—еҲ°еҫҲеӨ§еҲ¶зәҰпјҢиҖҢеҜ№еҚ°еҲ·еӨ§йқўз§Ҝзҡ„еҚ•иүІеҚ°еҲ·е“Ғе…·жңүдјҳеҠҝгҖӮ

еҮ№зүҲеҚ°еҲ·жҳҜдёҖз§Қеҝ«йҖҹеҸ‘еұ•зҡ„еҚ°еҲ·ж–№ејҸпјҢе®ғзҡ„еҺҹзҗҶдёҺеҮёзүҲеҚ°еҲ·жӯЈеҘҪзӣёеҸҚпјҢеҚ°зә№йғЁеҲҶеҮ№дәҺзүҲйқўпјҢйқһеҚ°зә№йғЁеҲҶеҲҷжҳҜе№іж»‘зҡ„гҖӮеҮ№дёӢеҺ»зҡ„йғЁеҲҶз”ЁжқҘиЈ…еЎ«жІ№еўЁпјҢеҚ°еүҚе°ҶеҚ°зүҲиЎЁйқўзҡ„жІ№еўЁеҲ®ж“Ұе№ІеҮҖпјҢж”ҫдёҠзәёеј 并ж–Ҫд»ҘеҺӢеҠӣеҗҺпјҢеҮ№йҷ·йғЁеҲҶзҡ„еҚ°зә№е°ұиў«иҪ¬еҚ°еҲ°дәҶзәёдёҠгҖӮ

еҮ№зүҲеҚ°еҲ·е…·жңүжІ№еўЁеҺҡе®һиүІи°ғдё°еҜҢгҖҒзүҲйқўй…ЈеҚ°еәҰејәгҖҒйўңиүІеҶҚзҺ°еҠӣејәзӯүдјҳзӮ№гҖӮеә”з”ЁиҢғеӣҙе№ҝжіӣпјҢйҖӮеҗҲеҗ„з§ҚеҚ°еҲ·жқҗж–ҷе’ҢеӨ§жү№йҮҸеҚ°еҲ·пјҢдҪҶеҲ¶зүҲиҙ№з”Ёй«ҳпјҢеҲ¶зүҲе·ҘиүәиҫғдёәеӨҚжқӮпјҢдёҚйҖӮеҗҲдәҺе°Ҹжү№йҮҸеҚ°еҲ·гҖӮеёёз”ЁдәҺз”»йқўзІҫзҫҺзҡ„еҢ…иЈ…еҚ°еҲ·гҖӮ

еӯ”зүҲеҚ°еҲ·еҸҲеҸ«дёқзҪ‘еҚ°еҲ·пјҢеҚіз”ЁдёқзҪ‘еҒҡзүҲжқҗзҡ„дёҖз§ҚеҚ°еҲ·ж–№ејҸгҖӮе…·дҪ“зҡ„ж–№жі•жҳҜеңЁеҚ°зүҲдёҠеҲ¶дҪңеҮәеӣҫж–Үе’ҢзүҲиҶңдёӨйғЁеҲҶпјҢзүҲиҶңзҡ„дҪңз”ЁжҳҜйҳ»жӯўжІ№еўЁзҡ„йҖҡиҝҮпјҢиҖҢеӣҫж–ҮйғЁеҲҶеҲҷжҳҜйҖҡиҝҮеӨ–еҠӣзҡ„еҲ®еҺӢе°ҶжІ№еўЁжјҸеҚ°еҲ°жүҝеҚ°зү©дёҠпјҢд»ҺиҖҢеҪўжҲҗеҚ°еҲ·еӣҫеҪўгҖӮе…¶еҺҹзҗҶдёәпјҢеңЁе№ійқўзҡ„зүҲжқҗдёҠжҢ–еүІеӯ”з©ҙпјҢ然еҗҺж–ҪеўЁпјҢдҪҝеўЁж–ҷйҖҸиҝҮеӯ”йҡҷжјҸеҚ°еҲ°жүҝеҚ°зү©дёҠгҖӮ

еӯ”зүҲеҚ°еҲ·зҡ„иҢғеӣҙе№ҝжіӣпјҢд»ҺеӨ§еһӢе№ҝе‘ҠеҲ°еҗҚзүҮйғҪеҸҜд»ҘеҚ°еҲ¶пјҢиҖҢдё”еҸҜд»ҘеңЁзәёеј гҖҒжЈүеёғгҖҒдёқз»ёгҖҒеЎ‘ж–ҷгҖҒзҺ»з’ғгҖҒжңЁжқҗгҖҒйҮ‘еұһзӯүеҗ„з§ҚжқҗиҙЁзҡ„жүҝеҚ°зү©дёҠеҚ°еҲ·гҖӮжҜ”еҰӮпјҡжҲ‘们常и§Ғзҡ„жұҪиҪҰдёҠзҡ„еӯ—дҪ“зҡ„еҚ°еҲ·гҖҒеӨ–еҢ…иЈ…зӣ’дёҠеӣҫж–Үзҡ„еҚ°еҲ·зӯүпјҢе°Өе…¶еңЁеҢ…иЈ…е®№еҷЁзҡ„瓶дҪ“еҚ°еҲ·дёҠе…·жңүдјҳеҠҝгҖӮ

ж•°з ҒеҚ°еҲ·жҳҜдёҖйЎ№з»јеҗҲжҖ§еҫҲејәзҡ„жҠҖжңҜпјҢж¶өзӣ–дәҶеҚ°еҲ·з”өеӯҗгҖҒз”өи„‘гҖҒзҪ‘з»ңйҖҡдҝЎзӯүеӨҡдёӘжҠҖжңҜйўҶеҹҹгҖӮжүҖи°“ж•°з ҒеҚ°пјҢе°ұжҳҜз”өеӯҗжЎЈжЎҲз”ұз”өи„‘зӣҙжҺҘдј йҖҒеҲ°еҚ°еҲ·жңәпјҢеҸ–ж¶ҲдәҶеҲҶиүІгҖҒжӢјзүҲгҖҒеҲ¶зүҲгҖҒиҜ•иҪҰзӯүжӯҘйӘӨпјҢеҜ№дәҺеҚ°йҮҸдёҚеӨ§(дёҚи¶і1000д»Ҫ)зҡ„еӣӣиүІеҚ°еҲ·дҪңдёҡйқһеёёжңүж•ҲпјҢд»Һиҫ“е…ҘеҲ°иҫ“еҮәпјҢж•ҙдёӘиҝҮзЁӢеҸҜд»Ҙз”ұдёҖдёӘдәәжҺ§еҲ¶пјҢе®һзҺ°дёҖеј иө·еҚ°гҖӮ

Lithographic printing, also known as offset printing, is one of the most commonly used printing methods. It was developed from early lithographic printing and has since been improved to use metal zinc or aluminum plates, its characteristic is that the image is printed on a rubber offset printing cylinder by the principle of oil-water repulsion, and then the image is printed on the paper by the cylinder. An offset press has multiple printing devices that transmit different colors. Lithographic printing register accurate, plate-making simple, low cost, soft color, rich levels. Relief Printing is the earliest invention and one of the oldest printing techniques, characterized by the printing on paper of images and text from the projection of the page. Its application principle is like a seal, raised place ink, directly printed on the substrate. This kind of printing method can not print multi-level, colorful printing, its performance is greatly restricted, and printing large area of monochrome printing has advantages. INTAGLIO printing is a rapid development of the printing method, its principle and relief printing is the opposite, the print part of the gravure plate, the non-print part is smooth. The concave part is used to fill the ink. Before printing, the ink on the printing plate is scraped clean, put on the paper and pressed, the concave part of the image is transferred to the paper. Gravure printing has the advantages of thick ink, rich color, good print quality and good color reproduction. Widely used, suitable for a variety of printing materials and mass printing, but plate-making cost is high, plate-making process is more complex, not suitable for small-batch printing. It is often used for the packaging and printing of exquisite pictures. The hole plate printing is also called the Silk Screen Printing, namely uses the silk screen to do the plate one kind of printing way. The specific method is to make a printing plate and plate film two parts, plate film is to prevent the ink through, and the part of the picture and text is through the external force of scraping the ink leakage to the substrate, thus forming a printing pattern. The principle is to cut holes in the plane plate, and then apply ink, so that the ink through the hole leakage to the substrate. Hole printing a wide range of printing, from large advertising to business cards can be printed, and can be printed on paper, cotton, silk, plastic, glass, wood, metal and other materials on the substrate. For example: We are common on the Car Font Printing, on the outer packaging box graphics and text printing, especially in the packaging container bottle printing has the advantage. Digital Printing is a comprehensive technology, covering printing electronics, computers, network communications and other technical fields. The so-called digital printing, that is, electronic files are transferred directly from the computer to the printing machine, eliminating the steps of color separation, plate-making, test run and so on. It is very effective for four-color printing operations with a small print volume (less than 1000 copies) , from input to output, the whole process can be controlled by a single person to achieve a printing.